Tavex uses cookies to ensure website functionality and improve your user experience. Collecting data from cookies helps us provide the best experience for you, keeps your account secure and allows us to personalise advert content. You can find out more in our cookie policy.

Please select what cookies you allow us to use

Cookies are small files of letters and digits downloaded and saved on your computer or another device (for instance, a mobile phone, a tablet) and saved in your browser while you visit a website. They can be used to track the pages you visit on the website, save the information you enter or remember your preferences such as language settings as long as you’re browsing the website.

| Cookie name | Cookie description | Cookie duration |

|---|---|---|

| tavex_cookie_consent | Stores cookie consent options selected | 60 weeks |

| tavex_customer | Tavex customer ID | 30 days |

| wp-wpml_current_language | Stores selected language | 1 day |

| AWSALB | AWS ALB sticky session cookie | 6 days |

| AWSALBCORS | AWS ALB sticky session cookie | 6 days |

| NO_CACHE | Used to disable page caching | 1 day |

| PHPSESSID | Identifier for PHP session | Session |

| latest_news | Helps to keep notifications relevant by storing the latest news shown | 29 days |

| latest_news_flash | Helps to keep notifications relevant by storing the latest news shown | 29 days |

| tavex_recently_viewed_products | List of recently viewed products | 1 day |

| tavex_compare_amount | Number of items in product comparison view | 1 day |

| Cookie name | Cookie description | Cookie duration |

|---|---|---|

| chart-widget-tab-*-*-* | Remembers last chart options (i.e currency, time period, etc) | 29 days |

| archive_layout | Stores selected product layout on category pages | 1 day |

| Cookie name | Cookie description | Cookie duration |

|---|---|---|

| cartstack.com-* | Used for tracking abandoned shopping carts | 1 year |

| _omappvp | Used by OptinMonster for determining new vs. returning visitors. Expires in 11 years | 11 years |

| _omappvs | Used by OptinMonster for determining when a new visitor becomes a returning visitor | Session |

| om* | Used by OptinMonster to track interactions with campaigns | Persistent |

| Cookie name | Cookie description | Cookie duration |

|---|---|---|

| _ga | Used to distinguish users | 2 years |

| _gid | Used to distinguish users | 24 hours |

| _ga_* | Used to persist session state | 2 years |

| _gac_* | Contains campaign related information | 90 days |

| _gat_gtag_* | Used to throttle request rate | 1 minute |

| _fbc | Facebook advertisement cookie | 2 years |

| _fbp | Facebook cookie for distinguishing unique users | 2 years |

New Discovery: Making Gold from Electronic Waste

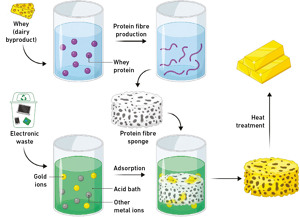

Swiss researchers have discovered a new way to extract gold from electronic waste. Their new sustainable method is based on a protein fibre sponge, which scientists obtain from whey, a by-product of the cheese making industry.

The Breakthrough

Scientists have recovered a 450-milligram nugget of 22 – carat gold from just 20 old computer motherboards. According to the results, the energy costs associated with the entire process and the acquisition of the source materials are fifty times less than the potential gold recovery.

According to the research, the nugget contained 22 carats (91 percent pure gold and the remaining portion was copper)

Source: ETH Zurich

This method of gold processing leverages a diverse array of waste and industrial by-products, making it both sustainable and cost-effective. By employing this technique of using acidic conditions and high temperatures, the extraction of gold from electronic device waste becomes simpler, more economical, and significantly more eco-friendly.

The transformation of common materials into gold was a quest that captivated early alchemists. In a groundbreaking advancement, Professor Raffaele Mezzenga from the Department of Health Sciences and Technology at ETH Zurich has introduced an innovative approach in this domain.

While it remains true that no one has successfully converted another chemical element into gold, as the alchemists once aspired to, scientists have achieved a notable discoveries. They have developed a method to reclaim gold from electronic waste using whey, a byproduct of cheese production.

E-waste contains a variety of valuable metals, including copper, cobalt and even significant amounts of gold. Recovering gold from used smartphones and computers is an attractive challenge given the growing demand for the precious metal. However, the recovery methods developed so far are energy intensive and often require highly toxic chemicals for processing. This new method is said to be highly effective, cost-effective and above all much more sustainable.

Economically Viable

According to scientific analyses, the new technology is commercially lucrative: the expenses for raw materials and energy consumption are a mere 2% of the value of the gold that can be extracted.

While researchers are still working to tailor this technology for consumer use, it is evident that electronic waste, although the most advantageous initial material for gold extraction, will not be the sole beneficiary. This method is poised to be equally effective in treating industrial waste and by-products from chip manufacturing or gold-plating operations, broadening its applicability beyond just e-waste.

The fact I love the most is that we’re using a food industry byproduct to obtain gold from electronic waste…You can’t get much more sustainable than that

ETH Zurich professor Raffaele Mezzenga said in a statement

He emphasises that this approach of transforming waste into gold is not only genuinely effective but also represents the pinnacle of sustainability, making it hard to envision a more eco-friendly solution.

Other Company’s Sustainability Efforts

Turning electronic waste into gold has also been occurring in other companies and countries as well. For example, by The Royal Mint. The Royal Mint brought the first sustainable metal technology to the UK. Royal Mint has partnered with Excir technology to also try and address the increased issue of electronic waste.

Key Takeaways

The revolutionary discovery by Swiss researchers of extracting gold from electronic waste marks a significant leap forward in both sustainability and technological innovation. This method, utilising a protein fibre sponge derived from whey – a byproduct of the food industry – presents a solution that is not only environmentally friendly but also economically advantageous.

The potential of this technology to reinvent waste processing is highlighted by the successful recovery of a 22-carat gold nugget from just 20 old computer motherboards. This demonstrates a chemical reaction method where the cost is exponentially lower than the value of the gold removed.

As the world grapples with the dual challenges of industrial waste including electronic industrial waste management and the sustainable recovery of precious metals, this method stands out for its minimal environmental impact and remarkable cost-efficiency.

The efforts of Professor Raffaele Mezzenga and his team at ETH Zurich extend beyond just the realm of waste recycling. They are reshaping the way we think about resource recovery, proving that the path towards a more sustainable future may very well lie in the innovative recycling of our electronic past.

This breakthrough not only echoes the alchemists’ dreams of transforming the mundane into the precious but does so in a way that harmonises with our contemporary needs for sustainability and environmental stewardship.